Fine Pole Permanent Magnetic Chuck

1,Suitable for surface grinders, spark machines, and wire cutting machine tools.

2,The pole spacing is fine, the magnetic force distribution is uniform, and the effect is particularly significant when processing small and thin workpieces.

3,There is no change in the precision of the worktable surface during demagnetization.

4,The panel is treated with special processing, leak-free, can prevent corrosion from cutting fluid, extend the service life, and can be used for a long time immersed in cutting fluid.

5,Six-side precision grinding processing, can be used vertically on wire cutting machines. High-performance magnetic steel is used in the disk, with strong suction and almost no residual magnetism.

6,The suction force can reach 100N/cm2.

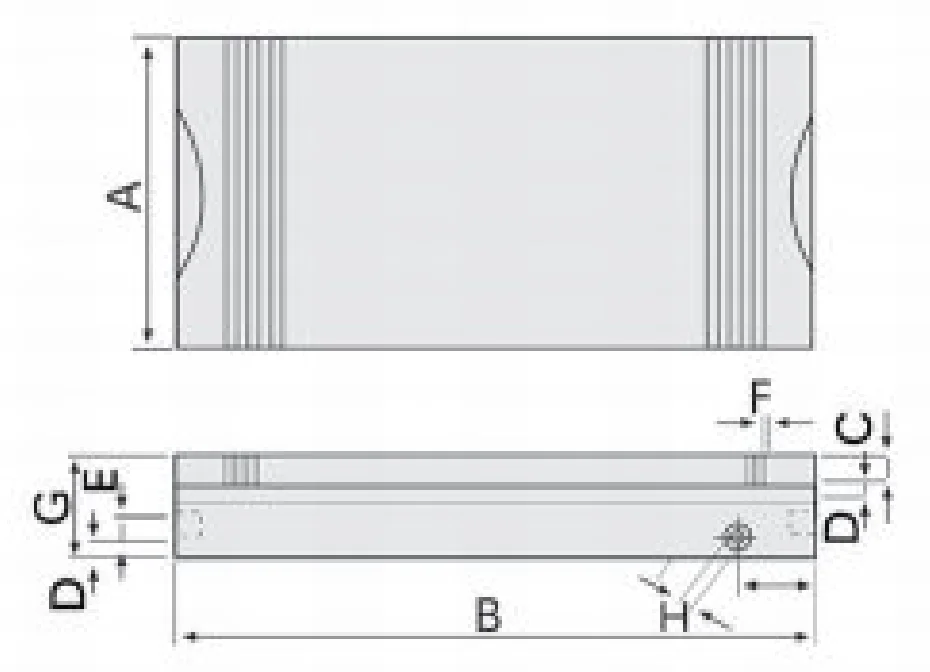

Fine Pole Rectangular Permanent Magnetic Chuck

Parameter

| British Model | Model | Main Dimensions (mm) | N.W (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | |||

| 4"*7" | XM91 100*175 | 100 | 175 | 18 | 4 | 10 | 2.0(0.5+1.5) | 45 | 7 |

| 5"*10" | XM91 125*250 | 125 | 250 | 18 | 4 | 10 | 2.0(0.5+1.5) | 45 | 13 |

| 6"*6" | XM91 150*150 | 150 | 150 | 18 | 4 | 10 | 2.0(0.5+1.5) | 45 | 9.4 |

| 6"*12" | XM91 150*300 | 150 | 300 | 18 | 4 | 10 | 2.0(0.5+1.5) | 45 | 19 |

| 6"*14" | XM91 150*350 | 150 | 350 | 18 | 4 | 10 | 2.0(0.5+1.5) | 45 | 22 |

| 6"*16" | XM91 150*400 | 150 | 400 | 20 | 4 | 10 | 2.0(0.5+1.5) | 45 | 26 |

| 6"*18" | XM91 150*450 | 150 | 450 | 20 | 4 | 10 | 2.0(0.5+1.5) | 45 | 29 |

| 8"*16" | XM91 200*400 | 200 | 400 | 20 | 4 | 10 | 2.0(0.5+1.5) | 45 | 35 |

| 8"*18" | XM91 200*450 | 200 | 450 | 20 | 4 | 10 | 2.0(0.5+1.5) | 45 | 39 |

| 8"*20" | XM91 200*500 | 200 | 500 | 20 | 4 | 10 | 2.0(0.5+1.5) | 45 | 43 |

| 10"*20" | XM91 250*500 | 250 | 500 | 20 | 4 | 10 | 2.0(0.5+1.5) | 45 | 45 |

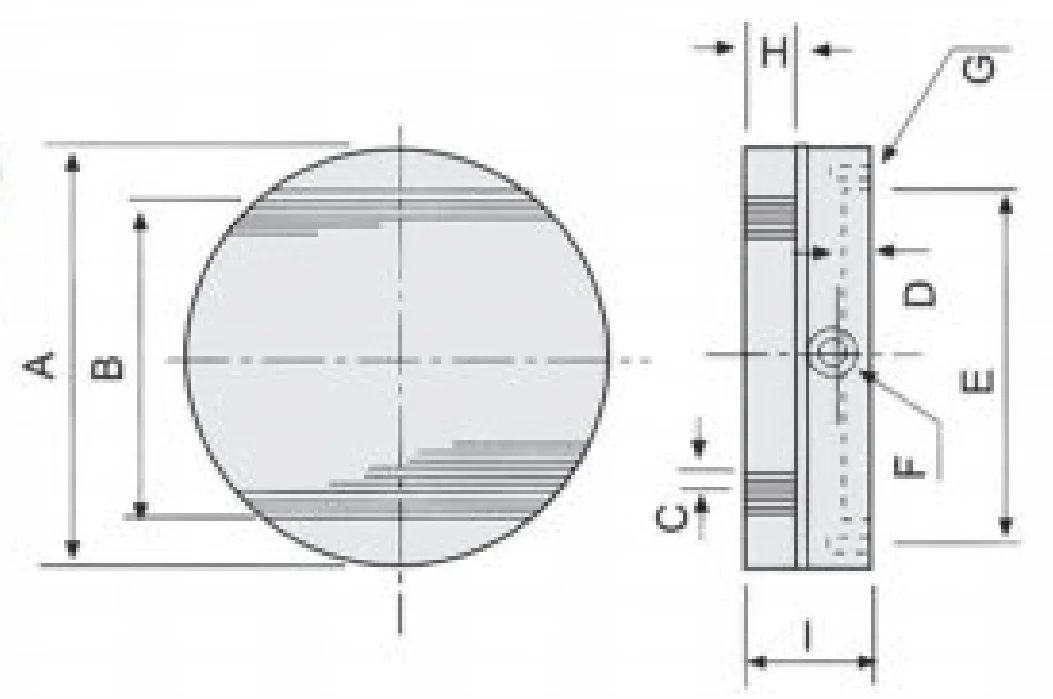

Fine Pole Circular Permanent Magnetic Chuck

Suitable for surface grinders, lathes, and machinist scribing, etc., for processing magnetic materials.

Product image

Parameter

| British Model | Model | Main Dimensions (mm) | N.W (kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | |||

| 5" | XM51 125 | 125 | 80 | 2.0(0.5+1.5) | 2 | 85 | 10 | M6 | 20 | 50 | 5.3 |

| 6" | XM51 160 | 160 | 115 | 2.0(0.5+1.5) | 2 | 120 | 10 | M8 | 20 | 50 | 8.4 |

| 8" | XM51 200 | 200 | 155 | 2.0(0.5+1.5) | 2 | 160 | 10 | M8 | 20 | 50 | 14 |

| 10" | XM51 250 | 250 | 205 | 2.0(0.5+1.5) | 2 | 200 | 10 | M10 | 20 | 50 | 22 |

| 12" | XM51 300 | 300 | 255 | 2.0(0.5+1.5) | 2 | 250 | 10 | M10 | 20 | 50 | 34.5 |

Customizable according to customer requirements.